Technical Structure of Gearless Motors:

February 11, 2025

VILLA ELEVATOR/HOME ELEVATOR

April 3, 2025This post is also available in:

العربية (Arabic)

The counterweight of an elevator is one of the essential components of the elevator system, playing a crucial role in maintaining balance and ensuring safe and efficient operation.

What is an Elevator Counterweight?

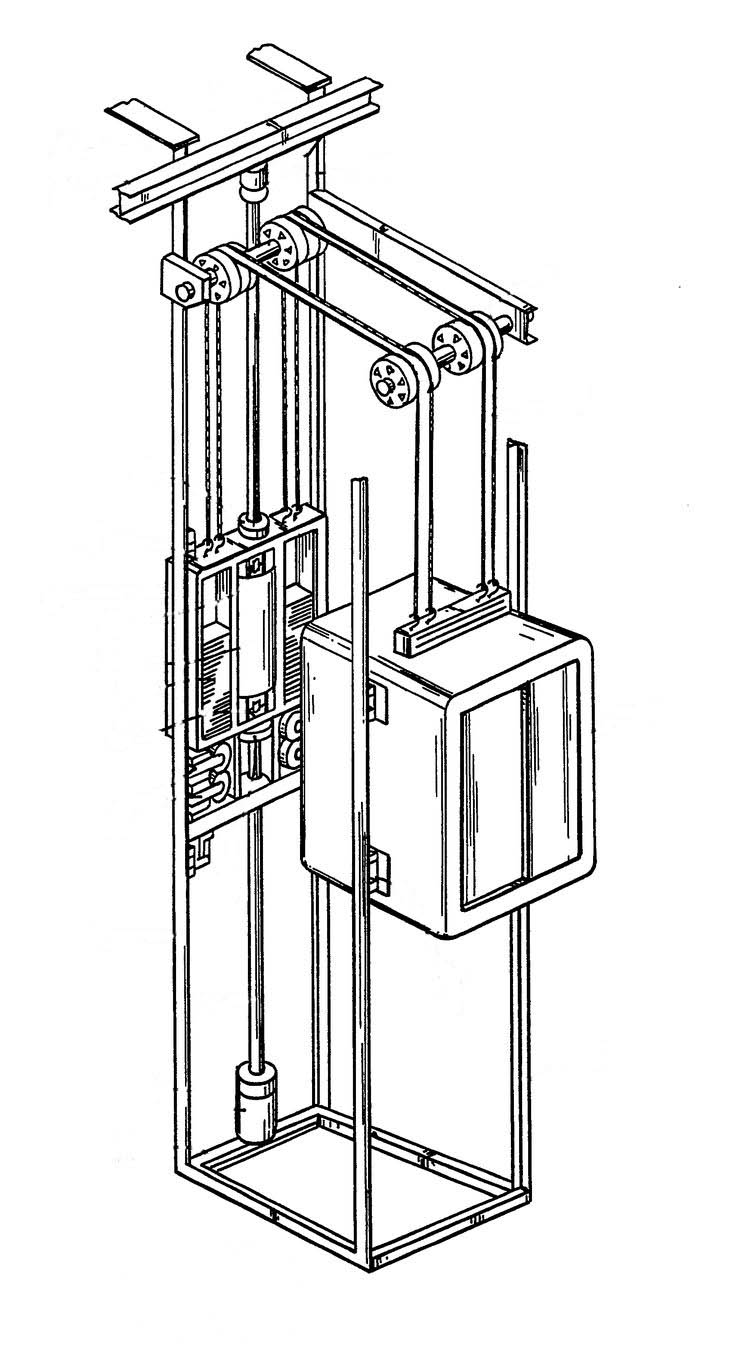

The elevator counterweight is a component used to balance the weight of the elevator car and reduce the load on the motor. These weights are typically made of concrete, cast iron, lead, or metal and are housed in a sturdy metal frame. The counterweight is connected to the elevator car via steel cables and pulleys, moving in the opposite direction as the car.

How to Calculate the Counterweight

To calculate the number of counterweights required, the following formula is used:

Number of Counterweights=Weight of Each CounterweightWeight of the Car+2Car Capacity

For example, if the car weighs 500 kg, its capacity is 750 kg, and each counterweight weighs 35 kg, the calculation is as follows:

500+2750=35500+375=35875=25

This means 25 counterweights of 35 kg each are needed.

Advantages of Counterweights

-

Reduced Motor Load: Counterweights reduce the energy consumption of the motor for moving the car.

-

Enhanced Safety: By reducing tension on the cables, the safety of the elevator system is improved.

-

Energy Efficiency: Counterweights significantly lower the motor's energy consumption.

-

Smoother Control: The movement of the elevator becomes smoother and more precise with counterweights.

-

Extended Equipment Lifespan: Reduced stress on the motor and cables increases the lifespan of the components.

Disadvantages of Counterweights

-

Heavy Weight: Handling and installing counterweights is challenging and costly due to their weight.

-

Transportation Costs: Transporting counterweights to the installation site requires special equipment and additional expenses.

-

Space Requirements: Counterweights occupy more space in the elevator shaft.

Types of Counterweights

Counterweights are categorized based on material, weight, and dimensions. Some common types include:

-

Concrete Counterweights: Made of concrete, these weights are often coated with plastic or galvanized sheets. They come in standard sizes such as 57, 67, 77, 87, 97, and 107 cm.

-

Lead Counterweights: These weights have a higher density and are suitable for limited spaces.

-

Cast Iron Counterweights: More expensive than concrete weights, they are designed for spaces with small shafts and high weight requirements.

-

Metal Counterweights: These are made by combining multiple metal pieces and securing them with bolts.

-

Plastic and Galvanized Counterweights: In the past, plastic weights were more popular due to their lower cost, but galvanized weights are now preferred for meeting safety standards.

- Concrete weight

- elevator-counter-weight

- Concrete weight

- Metal counterweight

- Galvanized metal

Cost of Counterweights

The price of counterweights depends on factors such as material, weight, and dimensions. Generally, concrete weights are cheaper, while cast iron and lead weights are more expensive. Larger sizes and heavier weights also increase production and transportation costs.

Key Considerations in Counterweight Design and Installation

-

Safety: The counterweight frame must be designed to prevent weights from falling out in case of sudden motor stoppage.

-

Precise Balance: Accurate calculation of the number and weight of counterweights is essential for optimal elevator performance.

-

Suitable Material: The material of the counterweight should be chosen based on environmental conditions and project requirements.

-

Compliance with Standards: Installation must adhere to safety and technical standards.

Conclusion

The elevator counterweight plays a vital role in maintaining balance and ensuring the safe and efficient operation of elevators. While it offers numerous benefits, such as energy savings, enhanced safety, and smoother control, it also has drawbacks, including heavy weight and transportation costs. Selecting the appropriate type of counterweight and accurately calculating the required number are essential for achieving optimal performance.