| Place of Origin | Zhejiang, China |

| Brand Name | FUJIHD |

| Usage | Residential Elevators |

| Drive Type | AC |

| Elevator Type | Passenger Elevators |

| Type | Elevators |

| Control | VVVF |

| Car cover | painted steel plate, decorative lamp |

| Car wall | Stainless steel hairline, etched mirror |

| Car door | Stainless steel hairline |

| Initial floor landing door | Stainless steel hairline |

| Other floor landing door | Painted steel palate |

| Rated Speed | 1.0~8.0m/s (Elevator ) |

| Certificates | CE, ISO900, EAC, GOST, SONCAP, CCVO, etc. |

| Warranty | 18 months |

Packaging and delivery

| Packaging Details | Upon buyer’s request usually in the wooden carton.like 40HQ, suitable for shipping |

| Port | Shanghai, China |

Supply Ability

| Supply Ability | 12000 sets |

High performance and intelligent CPU control system

Using a new generation of high-performance CPU technology and printing board system architecture, the elevator master control system is realized by the multi-chip architecture of motor drive, elevator control management, elevator communication and FPGA logic control. Multi-cpu cooperative work greatly improves the performance of elevator system, multi-CPU redundancy protection and FPGA hardware monitoring improve the stability and security of the system.

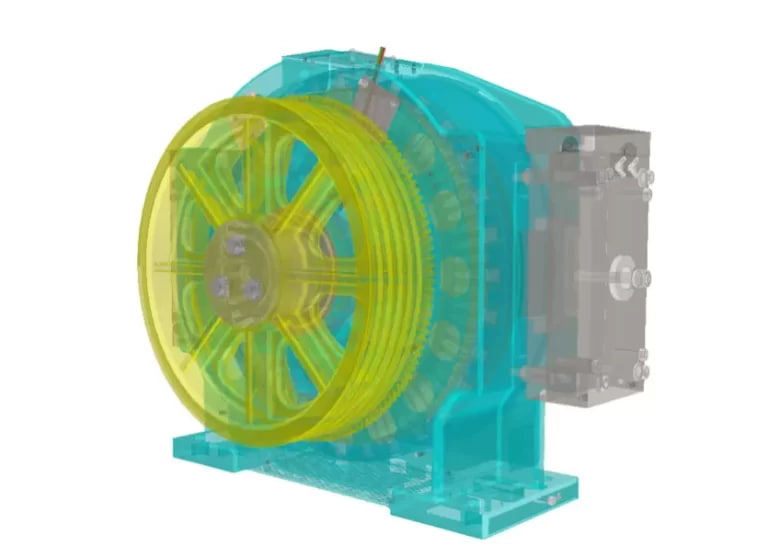

Traction Machine

The tractor is miniaturized by reducing shaft load, motor torque and brake torque. No additional excitation current and rotor current are required, which saves about 30% of energy compared to traditional turboworm tractors. The traction system with 2:1 rope winding ratio is adopted, and the traction machine is miniaturized by reducing shaft load, motor torque and braking torque. The brake adopts external direct acting drum structure, which has the characteristics of low energy consumption, simple structure, simple structure and easy maintenance

Special housing design provides stable and high structural rigidity Design isverified FEM and physical mechanical test

Designed by inner rotor. Possible to generate bigger torque with low noiseand vibration Provides comfortable ride

Solid construction for permissible shaft load Fs at the traction sheave up to30KN

Perfect rated motor, use of high-performance permanent magnet, degree ofprotection IP40, insulation class 155C ( F ), temperature control

The braker passed 2 million times braking. After the test, its performance isstill in specification. Safety is guaranteed

FUJIHD slim permanent magnet synchronous motor directly drives the door motor

Slim permanent magnet synchronous motor directly drives the door motor, reducing the volume of the door motor. The microcomputer controlled VVVF door motor speed

regulation system makes the door run intelligently, and can automatically adjust the running speed graphics and torque of the door according to the operating conditions of each station door (such as door weight, etc.) to achieve

accurate, smooth and quiet opening and closing action, while effectively improving the efficiency of the door motor.

Feature

Delicate Drive, Space-Saving

Compared with traditional motors, permanent magnet synchronous gearless traction machine has simpler structure, smaller volume, lighter weight, more flexible shape and size to meet the design of small machine room, so as to save the machine room space for users.

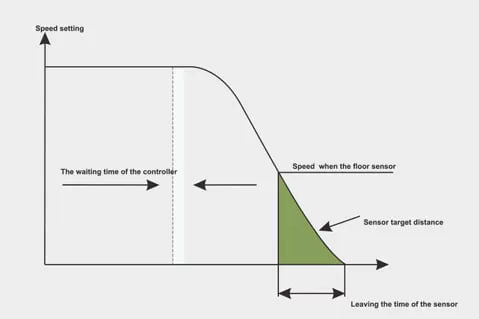

Intelligent Control, Precise and Reliable

Benefited from the control of high-precision encoder, the speed detection accuracy is rather high and the elevator stops very precisely.

Economic Operation, Green Energy-Saving

Energy transmission efficiency is up to more than 95%,starting current is small, heat productivity is small, energy-saving effect is obvious. Compared with traditional motors, it can save energy more than 30%. ln addition, there is no need for the complex lubricating system of the traditional motor, which avoids oil nollution and makes the maintenance simper.

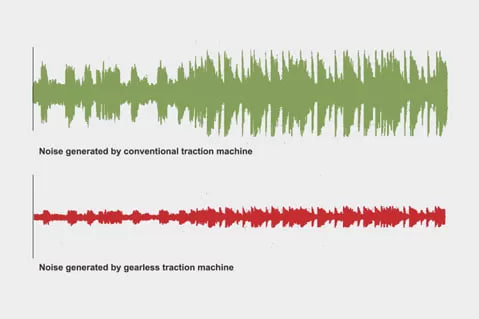

Mute Operation, Smooth and Comfortable

Gearless motor is driven by electro-magnetic force with low-speed non-contact operation, which avoids mechanical wear.vibration and noise of reduction box during the transmission process, and makes the elevator run very smoothly.

Parameter Table

Persons | (kg) | (m/s) | Net size of car (mm) | Net size of door D.WxD.H (mm) | Shaft size (mm) | Machine room size (mm) | |||

C.WxC.DxD.H | 2P Central opening | H.WxH.D | HR.H | PIT | MR.WxMR.D | MR.H | |||

6 | 450 | 1.0 | 1400x850x2300 | 800×2100 | 2000×1800 | 4000 | 1500 | 2000×1800 | 2500 |

1.5/1.75 | 4400 | ||||||||

8 | 630 | 1.0 | 1400×1100×2300 | 800×2100 | 2000×2050 | 4200 | 1500 | 2000×2050 | 2500 |

1.5/1.75 | 4400 | 1600 | |||||||

10 | 800 | 1.0 | 1400x1350x2300 | 800×2100 | 2000×2300 | 4200 | 1500 | 2000×2300 | 2500 |

1.5/1.75 | 4400 | 1600 | |||||||

2.0 | 4800 | 1800 | |||||||

2.5 | 2000 | ||||||||

13 | 1000 (1050) | 1.0 | 1600x1450x2300 1100x2300x2300 (Residence/stretcher elevator) | 900×2100 | 2200×2400 2050×2850 (Residence stretche elevator) | 4200 | 1500 | 2200×2400 2050×2850 (Residence/ stretcher elevator) | 2500 |

1.5/1.75 | 4400 | 1600 | |||||||

2.0 | 4800 | 1800 | |||||||

2.5 | 2000 | ||||||||

3.0 | 5200 | 2600 | |||||||

3.5 | 5500 | 3100 | |||||||

4.0 | 6000 | 3850 | |||||||

16 | 1250 | 1.0 | 1900x1450x2300 | 1100×2100 | 2500×2400 | 4200 | 1500 | 2500×2400 | 2500 |

1.5/1.75 | 4400 | 1600 | |||||||

2.0 | 4800 | 1800 | |||||||

2.5 | 2000 | ||||||||

3.0 | 5200 | 2600 | |||||||

3.5 | 5500 | 3100 | |||||||

4.0 | 6000 | 3850 | |||||||

18 | 1350 | 1.0 | 1900x1550x2300 | 1100×2100 | 2500×2500 | 4200 | 1500 | 2500×2500 | 2500 |

.5/1.75 | 4500 | 1600 | |||||||

2.0 | 4800 | 1800 | |||||||

2.5 | 2000 | ||||||||

3.0 | 5200 | 2600 | |||||||

3.5 | 5500 | 3100 | |||||||

4.0 | 6000 | 3850 | |||||||

21 | 1600 | 1.0 | 1900x1800x2300 | 1100×2100 | 2500×2800 | 4200 | 1500 | 2500×2800 | 2500 |

1.5/1.75 | 4500 | 1600 | |||||||

2.0 | 4800 | 1800 | |||||||

2.5 | 2000 | ||||||||

3.0 | 5200 | 2600 | |||||||

3.5 | 5500 | 3100 | |||||||

4.0 | 6000 | 4000 | |||||||

6.0 | 1900x1800x2300 | 1100×2100 | 2700×2900 | 6350 | 5000 | 4200×2900 | 2500 | ||

10.0 | 1900x1800x2800 | 2800×3000 | 8800 | 7200 | 4300×3000 | 3800 | |||

26 | 2000 | 1.0 | 1900x2200x2300 | 1100×2100 | 2700×2800 | 4500 | 1500 | 2700×2800 | 2500 |

1.5/1.75 | 4700 | 1600 | |||||||

2.0 | 5000 | 1800 | |||||||

4.0 | 1900x2200x2800 | 1100×2100 | 3200×3000 | 6000 | 3850 4000 | 4700×3300 | 3800 | ||

6.0 | 6400 | ||||||||

8.0 | 7500 | 6000 | |||||||

10.0 | 8800 | 7200 | |||||||